Many don't realize it. But the LEGO group produces more tires than any other manufacturer in the world. In fact in 2011 LEGO made 381 million tires. The next closest competitor was Bridgestone with a mere 190 million tires. The down side of this is the monopoly LEGO has in the LEGO car model world, where as real cars have lots of manufactures competing for sales. This means real tire makers have to provide proof that their product is superior. However I have noticed a major lack of performance data for any or the LEGO tires. Philo has done some comparative traction tests. And lots of people have published weights and measurements. But beyond that how do the tires affect the performance of LEGO Technic and Mindstorms models?

2696 - 13 x 24

2696 is a solid rubber tire made for "Model Team" vehicles and saw some use in several of the Technic Universal building sets as well. It is a hard compound and can hold a lot of weight. It is the lightest tire in the test and has the lowest moment of inertia (MoI).

2857 - 20 x 30

2857 Is also an older tire, and is also solid. It is a softer compound than 2696 and had larger voids between the tread. the wheel is a smooth cylinder and can slide out or spin inside of the tire.

44309 - 43.2 x 22 ZR

44309 is one of the smaller semi-pneumatic (s.p.) tires, and is what you will find in an NXT 2.0 set. The wheel is shared with the 55976 tire and can be used with rubber tread (caterpillar tracks). It's the lightest s.p. tire in the test and has very low moment of inertia (MoI).

55976 - 56 x 26

55976 is a very common tire and is also found in the NXT 1.0 sets.

41897 - 56 x 28 ZR

41897 has the same diameter as 55976 but the larger wheel moves the mass closer to the outer edge, this tire has slightly more weight and MoI than 55976

32019 - 62.4 x 20 S

32019 is often used for it's realistic look and heavy load capacity. The wheel has two circumferential ribs that act to stabilize the tall sidewalls. The wheel and tire have a lot of mass for their size, but the MoI is still less than the larger diameter tires.

61480 - 68.7 x 34

61480 is very common due to Technic's push for tractors and construction equipment a few years ago. It uses the familiar staggered void tread pattern but seems to have fairly high rolling resistance compared to other tire near it's size.

41893 - 68.8 x 36 H

41893 Dull and Shiny - I have two sets of these wheels. The dull rubber ones (pictures with gray wheels) came with my RC buggy and were made for play outside. I'm not sure where I got the shiny ones, but it has the more common tire compound. The difference in weight was negligible. The dull tires had slight but consistently lower MoI. I haven't compared the traction values of these tires yet.

In a strange way the slower motors seemed to prefer the shiny version, while the faster motors moved more efficiently with the dull tires. I hope to spend some more time comparing these two.

44771 - 68.8 x 36 ZR & 44777 - 68.8 x 36 ZR Hard Plastic Tire

44771 and 44777 are the same diameter, and made to look similar. While 44771 is a typical s.p. tire, 44777 is a simple and light plastic one-piece tire and wheel. The later is intended for "stunt driving" with remote controlled models.

44777 is only 18 grams compared to 44771's 36 grams, and the MoI reflects this by being almost 30% lower. However the slippery, non-conforming nature of the plastic stunt wheel makes it slightly harder to roll, as reflected in the Joules per meter charts.

2902 - 81.6 x 15

2902 Made for motorcycle style creations, it is a large diameter soft compound tire with a narrow section width. Like 32019 the wheel has several circumferential ribs to stabilize the tire with heavy loads. The narrow width keeps the mass down relative to other large diameter tires, however the design (specifically those ribs) give it a pretty high MoI.

92912 - 94.3 x 38 R

92912 Was created for the LEGO Unimog and is the heaviest tire in this group. It's tread patter is similar to 32019's, simply made larger. This tire shares the same wheel as the 44771 and 54120. It has the highest MoI, even though it's diameter and width are less than 54120. It is a very sturdy tire and appears to hold more weight than any other s.p. tire in the group. It may be well suited for a heavy creation but takes the most power to accelerate.

54120 - 94.8 x 44 R

54120 Is the overall largest tire in the group even though it is 10 grams lighter than 92912 (58 grams vs 68 grams) as expected it's MoI is high, but its large diameter lends it well to creations that need to cover a lot of ground. Although stopping and going consumes a lot of power.

51380 - "Tire Large Motorcycle Front"

51380 Matches 54120's 94.8 mm height yet has half of the mass of 92912. This was the tire I expected to have the greatest sustained speed efficiency of the group.

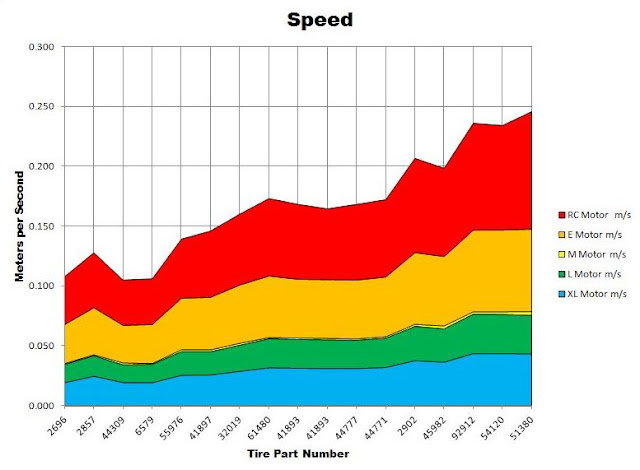

Here's some visual aides of how the tires and motors compared to each other.

The next set of charts display each motors rate of power consumption (Joules per Meter), with each combination of tires. A common thing I noticed through all of the test was how the power draw would usually drop slightly from the first test to the last test. My method of testing to put a set of tires on the vehicle then conduct three runs with each motor, the first run was the 13x24 tire with the RC motor. I ran this test three times, then turned the energy meter off while changing to the E motor. Again I would run the vehicle three times, then shut off the energy meter to change to the third motor and so on. I'm not yet sure why the economy improved, perhaps the motor turns easier with a little warming up. Or maybe the energy meter simply flows more watts when it's cold. My hypothesis leans towards the later possibility since the phenomenon was more pronounced on the more powerful motors. For each of these graphs the vertical bars display the average wattage of each motor/tire combinations during the three 3m test runs, and the purple bar is the average for each combination over the three runs. Lower numbers mean fewer Joules per second, the following info basically shows how much power the motor was consuming to turn the tires.

RC Motor specifics:

E Motor specifics:

|

| A selection of tires I will use for these tests. I haven't yet tested the tracks yet. There are many questions to be answered about the tires first. |

Granted there aren't too many people racing their creations on the ragged edge. There are some folks out there that build with function and practicality in mind. So I will delve into a multi part examination of how a selection of LEGO tires which are popular with powered creations can impact how they behave.

Many times in my life I have heard that big tires hurt your

mileage (MPG or Liters/100Km), and that better economy can be had with small

skinny tires. However most people don’t think about why this is.

-How does

rolling resistance play in to this?

-Don’t tall

bicycle tires go over bumps easier than little roller skate tires?

-What about

tire and wheel weight? -A top can spin for a long time, usually heavier tops

spin longer than light tops. Why doesn’t this hold true with tires on a car?

There are some fairly obvious reasons why passenger cars

aren’t driving around with tall tractor sized tires, but if diameter and mass

can help a tire keep rolling over bumps why do people put small skinny tires on

cars to improve mileage?

It would be very expensive for me to test this with real

tires, and the price of gasoline would almost be prohibitive. But I can scale

it down with LEGO tires and electric motors. Although it is kind of

embarrassing to consider the money I’ve invested into LEGO tires, the fact is I

have them. And the energy needed to test these small tires comes pretty easily

thanks to some rechargeable AA batteries. I also have a decent collection of

different LEGO motors demonstrating a wide spectrum of speed and torque. So now

I can compare different tire combinations with each of the motors and find the

most efficient combination (as well as the least efficient).

Philo did some excellent work analyzing most of the LEGO motors.

He basically built a dynamometer, and used a power supply with variable voltage

to examine how all of these motors perform at various voltage levels. From his

research we know maximum speed, maximum torque, and each motor’s ability to

turn electrical power in to power to move things. If you are familiar with

performance cars or hot rodding you may be familiar with Engine Dynamometers.

These are great tools to calculate how good a motor or engine is at producing

power (and in the case of internal combustion engines; tunning them to

perfection). But what you often don’t see on these is how parasitic drag from

things like transmissions, alternators, power-steering pumps, radiator fans,

and air conditioning pumps as well as driveline and axle losses affect these

engines (which often need more tuning to make them drivable in the real world).

All of this is done on something called a chassis dynamometer. A chassis dyno

has rollers under the car’s drive tires which are equipped with sensors and

wired to a computer which can translate torque and speed in to horsepower (the

equation is HP = FtLbs x RPM / 5252 if you’re wondering).

I didn’t build a LEGO sized chassis dyno (although that

could be possible…) But I can do the next best thing – build a drag strip! When

it comes to motors (or engines), power is a product of torque and speed. If you

know how much a vehicle weighs, and you know how quickly it can accelerate for

a set distance you can calculate the average power. If you break this distance

down you can refine the data to see how much power the motor is producing at a

given speed. The mix of LEGO motors I have demonstrate a varying range of speed

(RPM) and torque. Some motors turn slow with lots of torque, some turn fast

with little torque. I want to see how optimizing things like gearing,

tire/wheel selection, and chassis setup can maximize power put to the ground. In

most cases we are limited to 9 volts with LEGO motors (7.2 if using NiMH or 7.4

with LiPo rechargeable). So the best way to maximize power to the ground is

to maximize how efficiently we use those few volts in LEGO models. That is what

leads me to this battery of tests (pardon the pun). And to start off I need to know which tires

are best for this and how to best gear each motor to work with these tires,

this leads me to my first test.

There are lots of ways to approach this test. Mine is to

find the steady state power consumption of driving a simple LEGO vehicle with

different tires and motors. I originally planned on making a 10 meter long

track. But I didn’t want to work outside. I also didn’t want to drag all of my

stuff to a gymnasium and explain what I was doing to every random person that

stopped by. Luck would have it that I have enough room in my house to set up a

3 meter track. Thanks to the benefit of averages, I could simply run each

combination down this track say three times for a total effective length of 9

meters (pretty close to my original plan) and still get a good chunk of data.

Now I have five different motors, and 17 different types of tires for this

test. That results in 85 different motor/tire combinations, then I ran each

test three times that’s 255 runs. Each run was three meters, so I drove my

little LEGO vehicle 765 meters! That’s about 0.48 miles, which isn’t far to

walk or drive, but is a long way to chase a little LEGO vehicle for sure.

The motors I’m using are from fastest to slowest (in terms

of output shaft RPM) are:

5292 RC Buggy Motor

9670-1 PF E Motor (from the LEGO Education “Energy Meter” set.)

8883-1 PF M Motor

PF L Motor (new with the LEGO Rock Crawler)

8882-1 PF XL Motor

The tires are:

| Part # | Style | Size | Mass | Inertia |

| 2696 | Street | 13x24 | 14g | 1.391 |

| 2857 | Balloon | 20x30 | 19g | 1.753 |

| 44309 | Street | 43.2x22 ZR | 15g | 1.424 |

| 6579 | Balloon | 43.2x28 S | 17g | 1.486 |

| 55976 | Balloon | 56x26 | 17g | 1.851 |

| 41897 | Street | 56x28 ZR | 24g | 2.192 |

| 32019 | Street | 62.4X20 S | 33g | 2.775 |

| 61480 | Balloon | 68.7x34 | 30g | 3.136 |

| 41893 | dull | 68.8x36 Hd | 36g | 3.425 |

| 41893 | shine | 68.8x36 Hs | 36g | 3.478 |

| 44777 | PLASTIC | 68.8X36 ZRp | 18g | 2.711 |

| 44771 | Street | 68.8X36 ZR | 39g | 3.612 |

| 2902 | Balloon | 81.6x15 | 29g | 3.714 |

| 45982 | Balloon | 81.6x38 R | 40g | 4.288 |

| 92912 | Street | 94.3x38 R | 68g | 6.207 |

| 54120 | Balloon | 94.8x44 R | 58g | 5.833 |

| 51380 | Lg MtrCyc Ft | 36g | 4.656 |

Mass of each tire was measured on a simple kitchen scale, I’m sure there

is some error here, hence I didn’t bother with decimals. The inertia was determined

with a weight drop test. In this test I made a simple setup that I could place

on a counter and hold a LEGO axle a little more than one meter above the floor.

I then filled a medicine bottle with ballast to make a 100 gram weight. I tied

this weight on to a string and wrapped it around the LEGO axle, being careful

to not let the string double over its self (just one long wrap). I then placed

each wheel on the axle one by one and timed how long it took for the weight to

drop to the floor. This was done with a stop watch and is not super accurate

but does serve to demonstrate how the larger wheels are harder to accelerate than

smaller wheels. This would apply to real world mileage if you did a lot of

stop-and-go driving. I may perform a test later to see how much energy it takes

to accelerate each tire up to a given RPM.

Armed with this inertia data I decided to keep first test

slow, literally. I chose a gear ratio that was simple (for the sake of

consistency) but also was a decent compromise for the performance of all of the

motors. My three big concerns were: not going so fast with the RC motor as to

spin the tires; not to bog the soft hitting PF E motor; and not to take a whole

day with the strong, but slow PF XL motor. I found a 27:1 ratio easy to

build and a happy medium for all of the motors. With the RC motor and the

largest diameter tires the vehicle covered the three meter track in about 12

seconds, with the PF-XL motor and the smallest tires it took a little over two

minutes and thirty seconds!

This test was very time intensive, but necessary to pave the

way for follow on tests. With this test I was able to see how rolling

resistance of each of the tires impacted the efficiency of the test vehicle. Below are videos of two of the runs I did, the only difference between the two is the motor used. The first video is with the RC Buggy Motor (fastest of the group), the second is with the PF XL Motor (slowest of the group). The difference in speed is very obvious.

Lets take a closer look at the tires:

2696 is a solid rubber tire made for "Model Team" vehicles and saw some use in several of the Technic Universal building sets as well. It is a hard compound and can hold a lot of weight. It is the lightest tire in the test and has the lowest moment of inertia (MoI).

2857 - 20 x 30

2857 Is also an older tire, and is also solid. It is a softer compound than 2696 and had larger voids between the tread. the wheel is a smooth cylinder and can slide out or spin inside of the tire.

44309 - 43.2 x 22 ZR

44309 is one of the smaller semi-pneumatic (s.p.) tires, and is what you will find in an NXT 2.0 set. The wheel is shared with the 55976 tire and can be used with rubber tread (caterpillar tracks). It's the lightest s.p. tire in the test and has very low moment of inertia (MoI).

6579 - 43.2 x 28 S

6579 Is an old balloon tire. I think the four I have are from a 2000 or 2001 set.55976 - 56 x 26

55976 is a very common tire and is also found in the NXT 1.0 sets.

41897 - 56 x 28 ZR

41897 has the same diameter as 55976 but the larger wheel moves the mass closer to the outer edge, this tire has slightly more weight and MoI than 55976

32019 - 62.4 x 20 S

32019 is often used for it's realistic look and heavy load capacity. The wheel has two circumferential ribs that act to stabilize the tall sidewalls. The wheel and tire have a lot of mass for their size, but the MoI is still less than the larger diameter tires.

61480 - 68.7 x 34

61480 is very common due to Technic's push for tractors and construction equipment a few years ago. It uses the familiar staggered void tread pattern but seems to have fairly high rolling resistance compared to other tire near it's size.

41893 - 68.8 x 36 H

41893 Dull and Shiny - I have two sets of these wheels. The dull rubber ones (pictures with gray wheels) came with my RC buggy and were made for play outside. I'm not sure where I got the shiny ones, but it has the more common tire compound. The difference in weight was negligible. The dull tires had slight but consistently lower MoI. I haven't compared the traction values of these tires yet.

In a strange way the slower motors seemed to prefer the shiny version, while the faster motors moved more efficiently with the dull tires. I hope to spend some more time comparing these two.

44771 - 68.8 x 36 ZR & 44777 - 68.8 x 36 ZR Hard Plastic Tire

44771 and 44777 are the same diameter, and made to look similar. While 44771 is a typical s.p. tire, 44777 is a simple and light plastic one-piece tire and wheel. The later is intended for "stunt driving" with remote controlled models.

44777 is only 18 grams compared to 44771's 36 grams, and the MoI reflects this by being almost 30% lower. However the slippery, non-conforming nature of the plastic stunt wheel makes it slightly harder to roll, as reflected in the Joules per meter charts.

2902 - 81.6 x 15

2902 Made for motorcycle style creations, it is a large diameter soft compound tire with a narrow section width. Like 32019 the wheel has several circumferential ribs to stabilize the tire with heavy loads. The narrow width keeps the mass down relative to other large diameter tires, however the design (specifically those ribs) give it a pretty high MoI.

45982 - 81.6 x 38 R

45982 Getting in to the larger tires, this one is common with larger Technic creations. It is a tall profile tire (relatively tall sidewall compared to wheel diameter) and is soft. It seems to give under load easier than almost any of the other tires in the test. It uses the same wheel as the 41897 & 41893 tires. It is one gram lighter than the 44771 but has higher MoI due to it's larger diameter.

92912 - 94.3 x 38 R

92912 Was created for the LEGO Unimog and is the heaviest tire in this group. It's tread patter is similar to 32019's, simply made larger. This tire shares the same wheel as the 44771 and 54120. It has the highest MoI, even though it's diameter and width are less than 54120. It is a very sturdy tire and appears to hold more weight than any other s.p. tire in the group. It may be well suited for a heavy creation but takes the most power to accelerate.

54120 - 94.8 x 44 R

54120 Is the overall largest tire in the group even though it is 10 grams lighter than 92912 (58 grams vs 68 grams) as expected it's MoI is high, but its large diameter lends it well to creations that need to cover a lot of ground. Although stopping and going consumes a lot of power.

51380 - "Tire Large Motorcycle Front"

51380 Matches 54120's 94.8 mm height yet has half of the mass of 92912. This was the tire I expected to have the greatest sustained speed efficiency of the group.

Here's some visual aides of how the tires and motors compared to each other.

The next set of charts display each motors rate of power consumption (Joules per Meter), with each combination of tires. A common thing I noticed through all of the test was how the power draw would usually drop slightly from the first test to the last test. My method of testing to put a set of tires on the vehicle then conduct three runs with each motor, the first run was the 13x24 tire with the RC motor. I ran this test three times, then turned the energy meter off while changing to the E motor. Again I would run the vehicle three times, then shut off the energy meter to change to the third motor and so on. I'm not yet sure why the economy improved, perhaps the motor turns easier with a little warming up. Or maybe the energy meter simply flows more watts when it's cold. My hypothesis leans towards the later possibility since the phenomenon was more pronounced on the more powerful motors. For each of these graphs the vertical bars display the average wattage of each motor/tire combinations during the three 3m test runs, and the purple bar is the average for each combination over the three runs. Lower numbers mean fewer Joules per second, the following info basically shows how much power the motor was consuming to turn the tires.

RC Motor specifics:

E Motor specifics:

L Motor

XL Motor

So, in conclusion, just with this testing ~in layperson terms~ which tire/motor combo had the best performance and which had the worst?

ReplyDeleteSIS

"Best performance" is very subjective, I assume you want to know which tire has the best economy. The three tires I picked represent higher distance/lower energy (best economy) of small, medium and large tires. The gear ratio has not yet been optimized for each tire/motor combination (this test was like driving in first gear), that is the next step. After optimizing the motor-gear-tire relationship I will be able to say which tire can give you the best economy.

DeleteI'm looking for some big wheels for making a rock crawler (like 9398 set). I'v seen the 61480 in ebay... Do you think they are enough big? Thank you in advance

ReplyDeleteDepends on the scale (size) you want to build at. Lager tires will always crawl over things easier than small ones. As far as LEGO tires go the 64110 that come with the 9398 set would be the best.

Deletehttp://www.bricklink.com/search.asp?colorID=11&itemID=64110

Do you by any chance know which tire is best for driving straight?

ReplyDeleteDepends on the surface, for smooth surface go with a street style tire, for a rough surface one of the versions with lager voids in the treads and a softer compound will do better.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThe article has been very helpful and very informative. It provided people with new ideas about these

ReplyDeletebrisbane second hand tyres

second hand tyres

second hand tyre brisbane

second hand wheels brisbane

second hand tyres slacks creek

second hand tyres underwood

second hand tyres logan

second hand tyres logan city

second hand tyres brisbane

city tyres

Great, Check out the Best Sedan Cars in india

ReplyDeleteInformative Blog, check the list of latest tractor in India

ReplyDeleteNice Blog, Check New Tractor List

ReplyDeleteNice article.

ReplyDeleteWe are providing the best Tires From TireBuyer Coupons Code. I am sharing the link here, go and check it out.

Big Reason To Buy Tires From TireBuyer Coupons Code

https://www.autocarsindustry.com/big-reason-to-buy-tires-from-tirebuyer-coupons-code/

Information is useful keep posting.

ReplyDeleteTire Supplier In Qatar | Car Battery Replacement Doha | Lubricants Suppliers In Qatar | Car Tire Wholesale Suppliers Qatar

The most genuine post ever I read about this subject so far I should say you have cleared all the vital information. An obligation of appreciation is all together for sharing. Continue to do marvelous!

ReplyDeleteTyre Shop Near me

information blog!

ReplyDeleteSuch an amazing post, very informative and I will definitely suggest other people about it for sure.

ReplyDeletesource:https://tractorguru.in/tractor/new-holland-3630-tx-super-plus

Great!!!

ReplyDeleteThanks For sharing Information

https://tractorguru.in/tractor/swaraj-717

thanks for sharing information.

ReplyDeletehttps://tractorguru.in/mahindra-tractors

This is such an amazing article, am so interested

ReplyDeletein such articles to read. Thank you for sharing such an amazing article.

source: https://tractorguru.in/swaraj-tractors

ReplyDeleteamazing post, very informative and I will definitely suggest other people about it for sure.

eicher tractor price

Its really an Amazing quality stuff. Thanks for sharing this.

ReplyDeletehttps://vashishti.com